A Conversation with Norman R. McCombs, Pioneer of the Portable Oxygen Concentrator

By Carla Barnes, CAIRE Inc.~

When the LifeStyle Portable Oxygen Concentrator made its debut 20 years ago, the medical device was the first of its kind and promised a better quality of life for oxygen users worldwide.

Dramatically impacting the health of its users, the LifeStyle provided the ultimate mobility for millions of people who have been prescribed oxygen therapy as part of treatment for Chronic Obstructive Pulmonary Disease (COPD) and other debilitative respiratory conditions. No longer tethered to home oxygen systems or tanks that had to be refilled, individuals were able to enjoy more time away from home and even travel by air thanks to the new wearable device able to deliver oxygen powered by a rechargeable battery or electrical power.

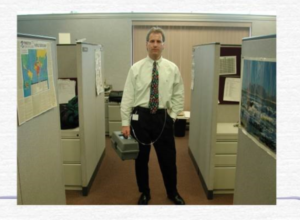

Norman R. McCombs, AASEE, BSME, ScD, NMTI, pioneer of the LifeStyle portable oxygen concentrator

The device was the product of creativity and ingenuity from a technological pioneer in the field of air separation — Norman “Norm” R. McCombs, AASEE, BSME, ScD, NMTI, then AirSep Corporation Senior Vice President of Research and Development, based in Amherst, a suburb of Buffalo, NY.

The 9.75-lb. LifeStyle POC not only delivered on its promise of high purity oxygen, but also proprietary, clinical features enabling the device to detect even the most faintest of breaths to ensure efficacious oxygen delivery.

This would be just the beginning of his extensive portfolio in this space — paving the way for the Focus, touted as the world’s smallest and lightest POC, and the even more innovative FreeStyle series.

His work would earn him countless awards from his industry peers, and, in 2013, the ultimate recognition for his contributions with the presentation of the prestigious National Medal of Technology and Innovation by President Barack Obama.

The award recognized McCombs’s development and commercialization of pressure swing adsorption oxygen-supply systems with a wide range of medical and commercial applications, leading to improved health, substantially reduced healthcare costs and a multitude of environmental applications.

An alumnus of the University of Buffalo, McCombs’ extensive resume includes private enterprise and a portfolio of patents that opened doors of opportunity as a consultant here in the US, and all over the world, particularly in the Asia-Pacific region, working with companies in Japan, Singapore, Thailand, New Zealand and Australia. In addition to his engineering pursuits, he would nurture his creative side — playing classical guitar, becoming a restaurateur, and authoring a book, “A Reason to Be.”

McCombs has cultivated a well-honed sense of curiosity throughout his life which drives him to experiment and pursue a variety of interests — a modern day Renaissance man.

Today, at 85, McCombs lives outside Las Vegas, NV, with his partner, Suky. He is working on a sculpture project designed for the campus of University of Nevada, Las Vegas.

His relationship to the UNLV began through engaging with the French gourmet society within the University’s William F. Harrah College of Hospitality. His mentorship of students through the program drew the attention of the Howard R. Hughes College of Engineering who has since recruited him to mentor young engineers and serve on the advisory board.

McCombs sat down with CAIRE recently to share his memories, celebrate the 20th anniversary of the LifeStyle, and to inspire the next generation of innovators in portable oxygen.

Question: You shared something pretty intriguing – that the LifeStyle portable oxygen concentrator actually finds its roots and development in the technology that supports wastewater treatment. Can you explain that?

Answer: Yes, I shared this with Larry Hughes, AirSep Vice President and General Manager, when I learned about the recent commercial project utilizing two oxygen plants – the AirSep ASV97000 VPSA Oxygen Systems (each producing 97,000 SCFH of oxygen) to upgrade the sewage treatment plants in Miami-Dade County.

That project is at an extremely large scale able supply 100 tons per day (TPD) of oxygen used in wastewater treatment, when you compare it to the early systems I developed for Linde were only treating up to 15 TPD, delivering about 7100 liters per minute (LPM), in 1972.

It was early in my career and we were targeting new methods of air separation. Zeolites have an affinity for nitrogen, and I had developed a very small four bed PSA oxygen system that produced 7 LPM.

Knowing this was an inexpensive way to make oxygen, development engineer Jack McWhirter asked me if I could scale up my system which had never been done before.

And me being a young man, I said, “Of course!”

A year later the first in the world non-cryogenic oxygen plant was supplying 15 TPD oxygen to treat the wastewater of Lederle Laboratories in Nanuet, NY. This was 50 years ago.

The same technology that separated the air for industrial purposes including wastewater treatment plants, among other commercial applications, had the potential to eliminate the containers of oxygen delivered to patients by medical equipment providers.

So, in fact, the tonnage plant is the great-grandfather of the LifeStyle.

Question: Share with us some memories around the development of the LifeStyle?

Answer: I wanted to prove we could do it. Taking a fishing tacklebox to house the necessary components, the team and I built the containerized demand device that could sense the inhale thanks to a pressure sensor capable of detecting a low vacuum of a shallow breath. Members of the team beta tested this new piece of technology—the portable oxygen concentrator.

Thomas Long, RRT-RCP, pictured holding the LifeStyle portable oxygen concentrator prototype built inside a fishing tacklebox.

Nobody knew what it was when they saw it.

Once we established that it worked, then came the further development of the form factor, and looking closely at the weight of the device. I went by the weight of my wife’s purse, around 10 pounds.

I really wanted it to look like something people wanted to buy. Something that was easy to use and understand — not complicated.

Question: Was there any particular component of the LifeStyle product development process that proved to be the most challenging or led to future innovations for POCs?

Answer: Indisputably it was the work that was done with the Federal Aviation Administration. All manufacturers of portable oxygen concentrators owe a debt of gratitude to Angelo “Ange” Liberatore, then AirSep Vice President of International Medical Sales, who passed away back in December (2021) at the age of 95. Ange was the spearhead of that work with the FAA and it was this work that opened the door for passengers to use a concentrator powered by battery during a commercial air flight.

LifeStyle portable oxygen concentrator

The LifeStyle portable oxygen concentrator featured a nickel-metal hydride battery, which would be approved in 2005 for use on commercial air flights — the first to earn this designation.

Later we would begin testing lithium ion batteries as we developed the FreeStyle POC.

We collaborated with Air New Zealand and flight surgeon Dr. Sandy Dawson to test lithium ion batteries to gain approval for commercial air flights. They were essentially the guinea pig, and were willing to try it. We had to develop a means to balance the batteries in order to avoid hot spots and fire aboard an aircraft. Ultimately we used this to prove usage to the FAA.

I don’t think anyone knows how difficult it was to get lithium ion batteries approved for on-board use. A lot of manufacturers have benefited from this work.

Question: What does it mean to you that the LifeStyle made such a global impact, and that your work continues today with the team at CAIRE?

Answer: It’s incredible really, and the 20th anniversary allows me to reminisce about the achievements and the people I worked shoulder to shoulder with. Before this I have never been able to put a bow on that part of my life. I am looking forward to visiting the Ball Ground manufacturing facility and visiting with the team to celebrate that accomplishment this year.

Question: What piece of advice would you give to those individuals who are innovating in the space of oxygen delivery, and particularly in the area of medical oxygen therapy technology.

Answer: I was given the ability to do this. It’s a God-given gift. And I believe, if you have been given a gift, take advantage of it.

For those people who haven’t been born with this in their DNA, or had these skills nurtured in their environment, I believe you make up for a lack of DNA with hard work. If you don’t know something, go learn it.

Don’t fall into the trap of not taking action yourself, but hoping someone else will. The four letter word hope has its place, but should not be a part of a design engineer’s vocabulary.

Carpe Diem!!!

- Norman R. McCombs speaks to CAIRE employees at the global headquarters at the celebration event in Ball Ground, GA, USA.

- From left, Barry Hassett, Vice President of Global Marketing, presents Norman R. McCombs with an award to honor his role as pioneer of the first portable oxygen concentrator, the LifeStyle, at the recent celebration event in Ball Ground, GA, USA.

- From left, Mr. Ken Hosako, Executive Vice President of CAIRE, and Norman R. McCombs talk during a recent celebration at the global headquarters in Ball Ground, GA, USA.

- CAIRE employees celebrate with Norman R. McCombs, center, at the recent celebration event.

- A special award was given to Norman R. McCombs at the celebration event in Ball Ground, GA, USA.

Carla Barnes has served as CAIRE Marketing Communications Manager for six years, following a career in higher education marketing and communications, and an extensive career working as an award-winning journalist in the newspaper industry.